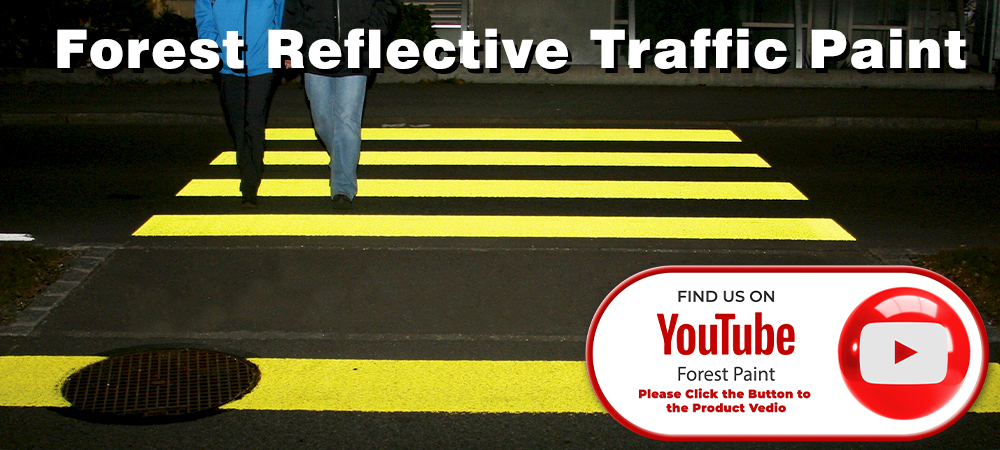

imveliso

Ukomisa ngokukhawuleza ipeyinti yokutshiza ebonakalisa uphawu lwendlela

IINKCUKACHA EZINGAKUMBI

- IVedio

- Iimpawu zeMveliso

- Isicelo seMveliso

- Iindawo zokwakha

- Unyango lomphezulu

- Indlela yokwakha

- Umqathango woKwakha

- EzoThutho noGcino

- Iphakheji

*Iimpawu zeMveliso:

1. Kulula ukupeyinta, ehlala ixesha elide, iyahlambeka kwayeukoma ngokukhawuleza;

2. Ifilimu yepeyinti inzima kwaye yomile ngokukhawuleza. Inoncamathelo ebalaseleyo kunye nokumelana nokunxiba. Unesiphumo esihle sokubonisa ubusuku;

3. Ukuqina okubonakalayo, umbala ongapheliyo, umaleko omnye kuphela ukufezekisa umphumo wokubonakalisa, nguisambatho esikhethekileyo sokuqina okubonakalayo;

4. Inokuthintela ukukhanya okukhanyayo kwe-ultraviolet, ukuthintela ukubola kombala kunye nokuxobuka, kwaye inokumelana nokutshiza kwetyuwa eyomeleleyo, ukuxhathisa kweasidi kunye nealkali;

5. Ipeyinti ebonakalisayoingatshizwa, ipeyintiwe, ibrashwe okanye iditshwe, kwaye kulula ukuyisebenzisa.

*Usetyenziso lweMveliso:

Yiisetyenziselwa indawo ezisicaba nezigudileyo, njenge-aluminium alloy, iglasi, ipayipi yensimbi kunye nezinye iindawo ezingalinganiyo ezifana nekhonkrithi yesamente kunye neenkuni. Yiesetyenziswa ngokubanzikwizibonelelo zothutho, iimpawu zendlela, iibhilibhodi, ukwandiswa kwegama lemoto, izithintelo zendlela, iimpawu zendlela, iimpawu zendlela, izibonelelo zokucima umlilo, iimpawu zokumisa ibhasi, imisebenzi yokuhlobisa, iimpawu zebhasi, iimoto zokugada amapolisa endlela, izithuthi zokhuseleko loluntu kunye nezithuthi zokuhlangula zobunjineli, kunye nezinye izithuthi ezikhethekileyo, kunye nemigca kaloliwe, iinqanawa, izikhululo zeenqwelo moya, imigodi yamalahle, njl njl.

*Iindawo zokwakha:

1. Ioli, amanzi kunye nothuli phezu kwe-substrate kufuneka isuswe ngokucokisekileyo ngaphambi kokwakhiwa, ngelixa igcina indawo yokusebenza yomile;

2. Emva kokuba i-primer ekhanyayo yomile, fafaza i-topcoat ekhanyayo;

3. Ngaphambi kokutshiza i-topcoat ekhanyayo, gxobhoza ipeyinti ngokucokisekileyo. Gxuma rhoqo ngexesha lokwakha.

4. Ubuninzi bengubo kwindawo ebonakalisayo, phantsi komqathango wokuqinisekisa amandla okugcoba, i-coating encinci kunye neyunifomu inesiphumo esihle kakhulu sokubonakalisa kwaye yenziwe ngexesha elinye.

*Unyango lomphezulu:

Umphezulu wesiseko wepeyinti kufuneka uqine kwaye ucoceke, ungabi neoli, uthuli kunye nezinye izinto ezingcolileyo. Umphezulu wesiseko kufuneka ungabi ne-asidi, i-alkali okanye i-condensation yomswakama. Emva kokusetyenziswa kwe-sandpaper, ipeyinti yendawo yendlela ingasetyenziswa, kwaye indawo yodonga lwesamente kufuneka ivalwe. Emva koko sebenzisa i-primer, i-topcoat; Ipeyinti yensimbi inconywa ukuba ifake i-matte varnish.

*Indlela yokwakha:

1. Ipeyinti ye-Akriliki yokuphawula indlela inokutshizwa kwaye ixutywe / iqengqeleke.

2. Ipeyinti kufuneka ixutywe ngokulinganayo ngexesha lokwakhiwa, kwaye ipeyinti kufuneka ihlanjululwe nge-solvent ekhethekileyo kwi-viscosity efunekayo yokwakha.

3. Ngexesha lokwakha, umgangatho wendlela kufuneka wome kwaye ucocwe ngothuli.

*Umqathango woKwakha:

Uthuli kunye nokungcola emhlabeni kufuneka kucocwe ngaphambi kokupeyinta. Indlela emanzi kufuneka yomiswe phambi kokwakhiwa. Ukuba i-viscosity iphezulu kakhulu, kufuneka ihlanjululwe nge-thinner ekhethekileyo.

*Ezothutho kunye noGcino:

Le mveliso inokutsha. Umlilo okanye imililo akuvumelekanga ngokungqongqo ngexesha lokwakha. Nxiba izixhobo zokukhusela. Indawo yokwakha kufuneka ingene umoya. Kuphephe ukuphefumla izinyibilikisi ngexesha lokwakha.