imveliso

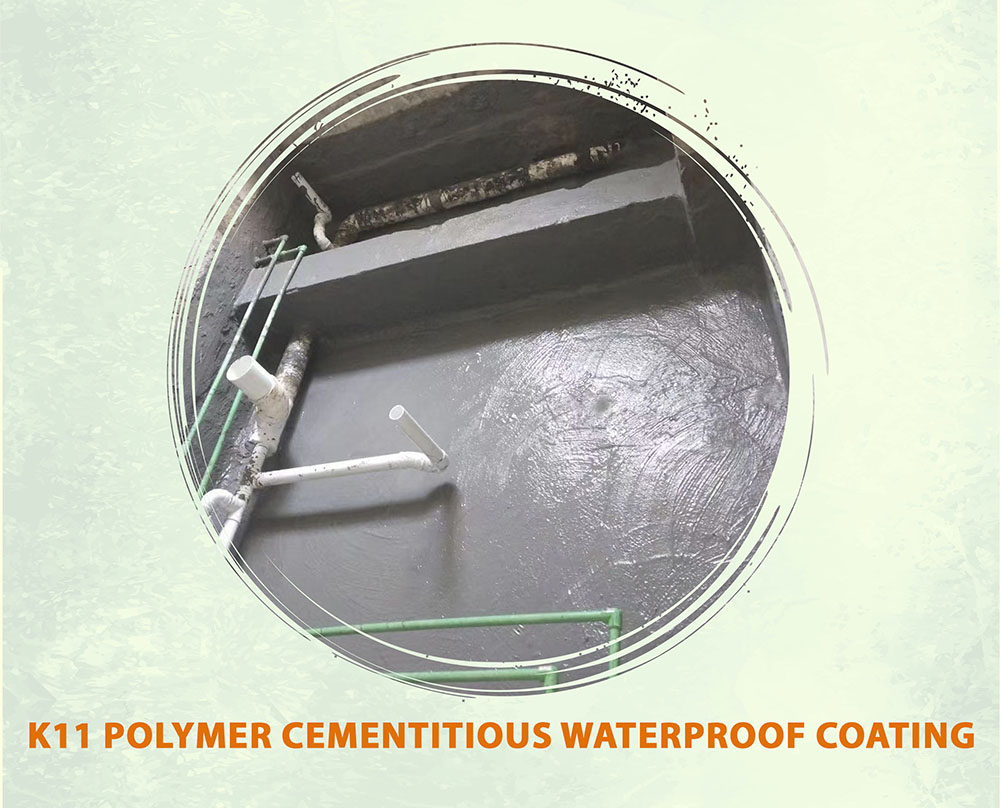

iBonding eyomeleleyo K11 ipholima yesamente engenamanzi

IINKCUKACHA EZINGAKUMBI

- Iimpawu zeMveliso

- Ukusetyenziswa kweMveliso

- Ukulungiselela isiseko

- IiParameters zeMveliso

- Ubugcisa bokwakha

- Qaphela

- EzoThutho noGcino

- Iphakheji

*Iimpawu zeMveliso:

1. Inokwakhiwa phezuumgangatho wesiseko omanzi;

2. Ukunamathela okuqinileyo kunye ne-substrate, izithako ezisebenzayo kwi-slurry zinokungena kwii-capillary pores kunye nemigodi ye-micro-crack kwindawo yesiseko se-cement ukuvelisa iikhemikhali. Idityaniswe kunye ne-substrate ukwenza i-crystalline exineneyo yomaleko ongenamanzi;

3. Emva kokumiswa kunye nokuqina, akuyimfuneko ukwenza umaleko wokukhusela udaka ukuze unamathisele ngokuthe ngqo iileyili kunye nezinye iinkqubo;

4. Isiphumo sokungangeni kwamanzi sihlala singatshintshi xa sisetyenziswa kwindawo ephezulu okanye ezantsi kwamanzi;

5. Icandelo eliphambili lale mveliso yizinto ezingabonakaliyo, ezingenayo ingxaki yokuguga kunye nefuthe elingapheliyo lokungena kwamanzi;

6. Ukungena komoya okulungileyo ukugcina iqela lomile;

I-7, imveliso engenabungozi, engenabungozi, ehambelana nokusingqongileyo.

*Usetyenziso lweMveliso:

Isakhiwo se-mulch yangaphakathi nangaphandle, i-samente ephantsi, unyango olungenamanzi kwiindonga zangaphakathi nangaphandle, ikhitshi kunye negumbi lokuhlambela.

Ukungangeni kwamanzi kwezakhiwo ezinezakhiwo ezizinzileyonjengezakhiwo zefektri, iiprojekthi zogcino lwamanzi, iindawo zokugcina ukutya okuziinkozo, iitonela, iindawo zokupaka ezingaphantsi komhlaba, iindonga zomgangatho, amadama okuqubha, amachibi amanzi okusela, njl.

*Ulungiselelo olusisiseko:

1. I-substrate kufuneka iqine, icwecwe, icoceke, ingabi nothuli, i-greasy, i-wax, i-ejenti yokukhulula, njl njl kunye nezinye i-debris;

2. Zonke ii-pores ezincinci kunye ne-trachoma zinokuxutywa kunye ne-Kl 1 powder ngamanzi amancinci ukuze zenze ubunzima obumanzi, kwaye bulula;

3. Ngaphambi kokupenda i-slurry, manzisa ngokupheleleyo i-substrate kwangaphambili, kodwa akufanele kubekho amanzi amileyo.

4. Umlinganiselo: Icandelo A slurry: Icandelo B powder, 1: 2 (umlinganiselo wobunzima) okanye i-1: 1.5 ngokweemfuno zokupakisha.

*Iiparamitha zeMveliso:

| Hayi. | Izinto zovavanyo | Iziphumo zeData | |

| 1 | Ixesha Lokoma | Umphezulu Wokoma, h ≤ | 2 |

| Hard Dray, h ≤ | 6 | ||

| 2 | Ukuxhathisa uxinzelelo lweOsmotic,Mpa ≥ | 0.8 | |

| 3 | Ukunganyibiliki, 0.3Mpa, 30min | engangeneki | |

| 4 | Ukuba bhetyebhetye,N/mm,≥ | Umthamo wotshintsho osecaleni, mm, | 2.0 |

| Ukubanda | ufanelekile | ||

| 5 | Mpa | Akukho ndawo yonyango | 1.1 |

| Umgangatho ongaphantsi omanzi | 1.5 | ||

| Umphezulu wealkali waphathwa | 1.6 | ||

| Unyango lokuntywiliselwa | 1.0 | ||

| 6 | Amandla acinezelayo, uMpa | 15 | |

| 7 | Amandla e-Flexural, uMpa | 7 | |

| 8 | Ukuxhathisa kwealkali | Akukho kuqhekeka, akukho kuxobulwa | |

| 9 | Ukumelana nobushushu | Akukho kuqhekeka, akukho kuxobulwa | |

| 10 | Ukuchasa umkhenkce | Akukho kuqhekeka, akukho kuxobulwa | |

| 11 | Ukucutheka,% | 0.1 | |

*Itekhnoloji yoKwakha:

Galela umgubo kwisikhongozelo esizaliswe lulwelo, shukumisa ngoomatshini imizuzu emi-3 de kungabikho mvula icolloid, emva koko mayime imizuzu emi-3 ukuya kwemi-5, emva koko uyishukumise kwakhona ukuze uyisebenzise. Ukuvuselela okwethutyana kufuneka kugcinwe ngexesha lokusetyenziswa ukuthintela imvula. Sebenzisa i-brush eqinile, i-roller okanye i-sprayer ukuxubha ngokulinganayo okanye ukutshiza i-slurry edibeneyo kwi-substrate emanzi; ulwakhiwo olunamaleko, isikhokelo sokuxubha soluhlu lwesibini kufuneka sibe perpendicular ukuya kumaleko wokuqala; ubungqingqwa ngamnye akufunekanga budlule kwi-1mm.

*Isaziso:

Ubushushu bokwakha yi-5℃-35℃; i-slurry emva kokulungelelaniswa kufuneka isetyenziswe ngaphakathi kweyure eli-1; umgangatho wesiseko kufuneka uhlaziywe kwakhona ngaphambi kokuba isiseko se-cement calendering sakhiwe; kucetyiswa ukuba kusetyenziswe i-ceramic tile bonding xa ubeka iileyile kwi-agent ye-layer engangeni manzi.

*Ezothutho kunye noGcino:

1. Liphephe ilanga nemvula, gcina kwindawo eyomileyo nengena umoya.

2. Xa uthutha, kufuneka ubekwe ngokuthe tye ukuthintela ukuthambeka okanye uxinzelelo oluthe tyaba, kwaye ugubungele ngelaphu leshidi ukuba kuyimfuneko.

3. Ngaphantsi kweemeko eziqhelekileyo zokugcinwa kunye nokuthutha, ixesha lokugcina ngunyaka omnye ukususela kumhla wokuvelisa.